- TOP

- >

- Long-Term Environmental Vision

We have a conception of a future society as one that is low-carbon and recycling-based. To achieve it, we have formulated the Tokyo Steel EcoVision 2050 with our specific approach of “taking action, now.”

Long-Term Environmental Vision: Tokyo Steel EcoVision 2050

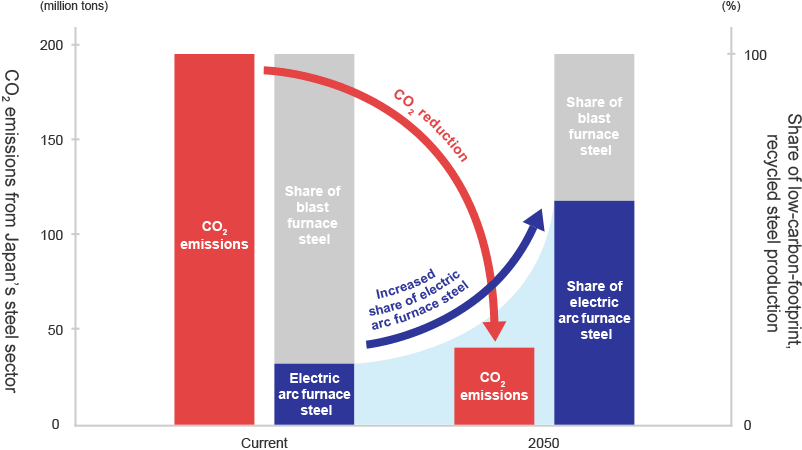

To reduce Japan’s CO2 emissions by 80% by 2050, the steel industry must reduce its emissions by 160 million tons, or 13% of the total national target.

Meanwhile, steel scrap is increasing in Japan, such that, by 2050, the amount is expected to be sufficient to satisfy domestic steel demand.

To address the two social themes—reducing increasing CO2 emissions and circulating steel scrap as a valuable resource in Japan—in order to achieve the ideal society in 2050, as well as a recycling-based society and low-carbon society, we at Tokyo Steel have formulated our long-term environmental vision, the Tokyo Steel EcoVision 2050. As a leading electric arc furnace steelmaker that has sought new areas of steel products, we view our EcoVision not only as what we can do for society but also as a challenge for which we should play a leading role.

The Tokyo Steel EcoVision 2050 focuses on the development of a low-carbon society and recycling-based society to considerably reduce CO2 emissions in Japan by supplying electric arc furnace steel as low-carbon-footprint, recycled steel and to improve resource efficiency by more effectively using steel scrap as a valuable resource in Japan, with the goal of achieving the ideal society in 2050.

In Pursuit of a Low-Carbon Society

To develop a low-carbon society, efforts in the steel sector, which emits 15% of Japan’s total CO2 emissions, are indispensable. We will help reduce CO2 emissions in society through the production and sales of electric arc furnace steel, which is low-carbon-footprint and recycled.

- 1.We will increase the production of electric arc furnace steel as low-carbon-footprint, recycled steel, the CO2 emissions of which are a quarter of those of blast furnace steel.

- 2.We will reduce CO2 emissions from the steel sector in Japan by increasing the market share of low-carbon-footprint, recycled steel.

- 3.We will reduce CO2 emissions from our entire product life cycle by saving energy and using electricity generated from non-fossil fuels, including renewables.

Conceptual chart toward reduction in CO2 and increase in domestic crude steel production

In Pursuit of a Recycling-Based Society

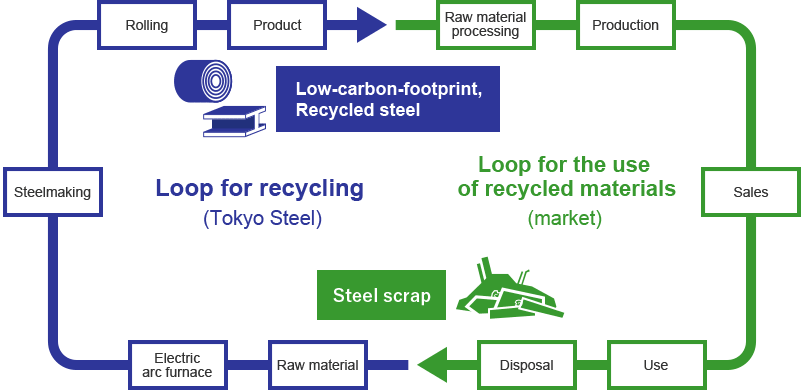

We believe that a recycling-based society requires an ever widening and strengthening “closed steel loop,” comprising a loop for recycling and a loop for the use of recycled materials, with our electric arc furnace steel as low-carbon-footprint, recycled steel and with steel scrap as the raw material for our steelmaking.

- 1.We will improve resource efficiency by increasing the use of electric arc furnace steel made from steel scrap, which is low-carbon-footprint, recycled steel, in the market.

- 2.We will promote recycling by increasing the procurement of steel scrap collected in Japan and by increasing the production of low-carbon-footprint, recycled steel made from steel scrap.

Closed steel loop

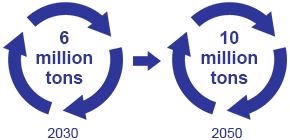

Challenges Toward 2030 and 2050

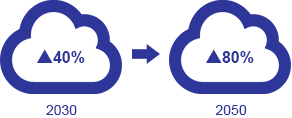

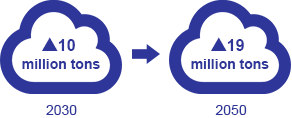

In pursuit of a low-carbon society and recycling-based society, we aim to achieve numerical targets that we have set toward 2030 and 2050.

We will make significant contributions to achieve the ideal society in 2050 as well as to bring about a low-carbon society and recycling-based society through the reduction of CO2 emissions from the entire life cycle of our products and advanced use of steel scrap in Japan.

Tokyo Steel EcoVision 2050

Achieving a low-carbon society

Note: Reductions in CO2 emissions are reductions from the fiscal 2013 level

Note on assumptions: In WWF Japan’s Long-Term Scenarios for Decarbonizing Japan, renewables account for 40% of primary energy supply by 2030 and 100% by 2050 under the 100% renewable energy scenario.

Note: CO2 emissions reduction by 2030 associated with production and sales of our low-carbon-footprint products = ▲1.7 t-CO2/t × Quantity of alternatives to blast furnace products

CO2 emissions reduction by 2050 associated with production and sales of our low-carbon-footprint products = ▲1.9 t-CO2/t × Quantity of alternatives to blast furnace products

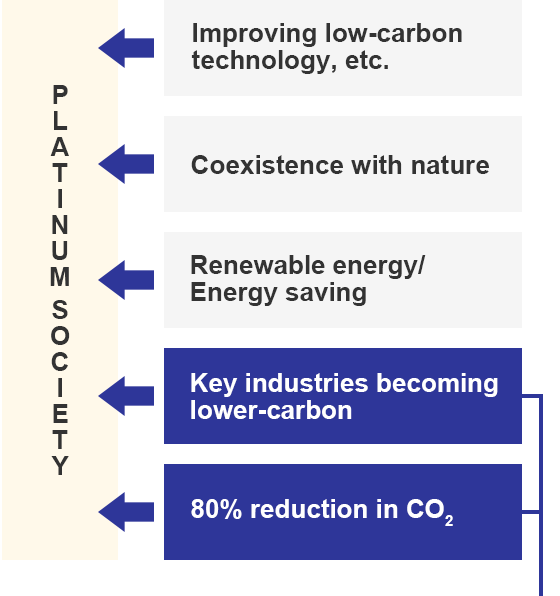

Proposing electric arc furnaces in the steel industry

New Vision 2050, co-authored by Hiroshi Komiyama (former president of the University of Tokyo) and Koichi Yamada (executive advisor to the President’s Office of the University of Tokyo) and published by Nikkei BP, calls a sustainable society in harmony with the environment a “platinum society” and proposes the use of electric arc furnaces in the steel industry as one of the initiatives toward achieving a low-carbon society.

Platinum society

- Key industries becoming lower-carbon

- 80% reduction in CO2

- Improving low-carbon technology, etc.

- Coexistence with nature

- Renewable energy/Energy saving

Use of electric arc furnaces in the steel industry

■Establishing material circulation systems

→Produce all steel products from scrap to reduce energy consumption.

■A shift in the steel industry—achieving 80% reduction in CO2 emissions

→The steel industry, which is emitting 200 million tons of CO2 per year (largest among all industries) should cut emissions by 160 million tons, or 13% of Japan’s total emissions, by shifting from blast furnace steel to electric arc furnace steel to double the production of electric arc furnace steel to 50 million tons.

Action Plan

To achieve the Tokyo Steel EcoVision 2050, our long-term environmental vision, we will take following actions in the respective areas:

| Category | Action plan | Relevance to Tokyo Steel EcoVision2050 | |

|---|---|---|---|

| Achieving low-carbon society | Achieving recycling-based society | ||

| Internal initiatives | Aggressively make investments in energy saving and review production, procurement and transportation processes to cut per-unit CO2 emissions by more than 1% every year. Carry out activities to reduce per-unit CO2 emissions by 40% by 2030 and by 80% by 2050 from the FY2013 level. | ○ | |

| Review production process, etc. to achieve zero emissions at four plants in Japan. | ○ | ||

| Enhance the attractiveness of low-carbon-footprint, recycled steel through continued technological development and product development to increase market share of low-carbon-footprint, recycled steel. | ○ | ○ | |

| Increase the use of electricity generated from non-fossil fuels, including renewables, by the wider use of such electricity. | ○ | ||

| Initiatives with heavy users | Make efforts to increase the use of our low-carbon-footprint, recycled steel1, which helps achieve low-carbon, recycling-based urban development, by putting forward proposals to corporate customers, the government, universities, research institutions, etc. and collaborating with them. | ○ | ○ |

| Expand horizontal recycling2 with corporate customers that share the vision of achieving a low-carbon society/recycling-based society, and increase projects to promote the use of low-carbon-footprint, recycled steel through continued technological development3 for advanced use of steel scrap. | ○ | ○ | |

| Increase closed-loop circular transactions, in which we recycle steel and deliver low-carbon-footprint, recycled steel, by improving the collection rate of processed scrap generated when corporate customers use our products. | ○ | ||

| Encourage the central and local governments to designate electric arc furnace steel as low-carbon-footprint, recycled steel for public investment to achieve a low-carbon society and recycling-based society. | ○ | ○ | |

| Work with the government, corporate customers, etc. on closed-loop circular transactions, in which steel resources in demolished public properties are recovered and our low-carbon-footprint, recycled steel is delivered to new public properties. | ○ | ○ | |

| Initiatives with suppliers | Enhance green partnerships with domestic steel scrap companies that share the vision of achieving a low-carbon society and recycling-based society to increase steel scrap collected. | ○ | |

| Contribute to wider use of electricity generated from non-fossil fuels, including renewables. | ○ | ||

| Other | Boost collection and effective use of steel resources, etc. with the use of our electric arc furnaces and recycling treatment4 of waste generated by local municipalities and businesses. | ○ | |

Internal initiatives

| Action Plan | Relevance to Tokyo Steel EcoVision2050 | |

|---|---|---|

| Achieving low-carbon society | Achieving recycling-based society | |

| Aggressively make investments in energy saving and review production, procurement and transportation processes to cut per-unit CO2 emissions by more than 1% every year. Carry out activities to reduce per-unit CO2 emissions by 40% by 2030 and by 80% by 2050 from the FY2013 level. | ○ | |

| Review production process, etc. to achieve zero emissions at four plants in Japan. | ○ | |

| Enhance the attractiveness of low-carbon-footprint, recycled steel through continued technological development and product development to increase market share of low-carbon-footprint, recycled steel. | ○ | ○ |

| Increase the use of electricity generated from non-fossil fuels, including renewables, by the wider use of such electricity. | ○ | |

Initiatives with heavy users

| Action Plan | Relevance to Tokyo Steel EcoVision2050 | |

|---|---|---|

| Achieving low-carbon society | Achieving recycling-based society | |

| Make efforts to increase the use of our low-carbon-footprint, recycled steel1, which helps achieve low-carbon, recycling-based urban development, by putting forward proposals to corporate customers, the government, universities, research institutions, etc. and collaborating with them. | ○ | ○ |

| Expand horizontal recycling2 with corporate customers that share the vision of achieving a low-carbon society/recycling-based society, and increase projects to promote the use of low-carbon-footprint, recycled steel through continued technological development3 for advanced use of steel scrap. | ○ | ○ |

| Increase closed-loop circular transactions, in which we recycle steel and deliver low-carbon-footprint, recycled steel, by improving the collection rate of processed scrap generated when corporate customers use our products. | ○ | |

| Encourage the central and local governments to designate electric arc furnace steel as low-carbon-footprint, recycled steel for public investment to achieve a low-carbon society and recycling-based society. | ○ | ○ |

| Work with the government, corporate customers, etc. on closed-loop circular transactions, in which steel resources in demolished public properties are recovered and our low-carbon-footprint, recycled steel is delivered to new public properties. | ○ | ○ |

Initiatives with suppliers

| Action Plan | Relevance to Tokyo Steel EcoVision2050 | |

|---|---|---|

| Achieving low-carbon society | Achieving recycling-based society | |

| Enhance green partnerships with domestic steel scrap companies that share the vision of achieving a low-carbon society and recycling-based society to increase steel scrap collected. | ○ | |

| Contribute to wider use of electricity generated from non-fossil fuels, including renewables. | ○ | |

Other

| Action Plan | Relevance to Tokyo Steel EcoVision2050 | |

|---|---|---|

| Achieving low-carbon society | Achieving recycling-based society | |

| Boost collection and effective use of steel resources, etc. with the use of our electric arc furnaces and recycling treatment4 of waste generated by local municipalities and businesses. | ○ | |

- 1 We are producing and sellinghigh-standard electric arc furnace H-beams, square-shapedTSC295 steel pipe, and other low-carbon-footprint, recycled steel products.

- 2 We are making efforts to achieve “Car to Car” recycling.

- 3 We are working with leading environmental companies, including Ricoh Co., Ltd. and Panasonic Corporation.

- 4 We aretreating dry-cell batteriesat our Okayama Plant.