- TOP

- >

- Our Commitment

Tokyo Steel manufactures low-carbon-footprint steel products using steel scrap as the main raw material. Being at the forefront of resource recycling, we are committed to working seriously on measures to combat climate change.

Message from President

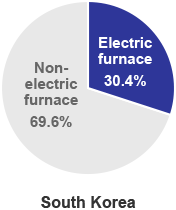

Tokyo Steel, a company engaged in the recycling of steel resources, has been committed to adding value to its products from the very beginning. In the past, skeptics in the industry said that it would be impossible to produce even senior-sized H-beams by the electric arc furnace process (i.e., scrap-based steelmaking). Today, however, we are Japan’s top manufacturer of H-beams, offering a full lineup of products, including even jumbo-sized products (the maximum size as per JIS). Likewise, when we started production of hot rolled coils in 1991, some suggested that it would be extremely difficult to produce them by the electric arc furnace process. Contrary to their predictions, in peak years we have supplied more than 1.5 million tons of these products to Japanese and international customers.

Tokyo Steel has been developing technology to control and effectively utilize particular elements contained in steel scrap with the goal of recycling steel scrap―a valuable domestic resource in Japan―into high value-added steel products. In pursuing resource recycling in the real sense of the term, we have taken on the extremely difficult challenges involved in developing and manufacturing products mainly from general heavy scrap as obsolete scrap without relying on blast furnace pig iron or high-grade scrap such as busheling scrap, and have achieved success. Manufacturing recycled steel products with the electric arc furnace process generates one-quarter as much CO2 as steel manufacturing with the blast furnace converter process, which is currently the mainstream process in steel production, and therefore is indispensable in transition to a low-carbon society as one of the measures for arresting global climate change.

Recycling of steel products with the electric arc furnace process is truly the most effective in terms of achieving a recycling-based society and low-carbon society at the same time. To contribute to Japan’s target of reducing greenhouse gas (GHG) emissions by 80% by 2050 while making advanced use of steel scrap that, in aggregate, amounts to several decades’ worth of domestic steel demand, Tokyo Steel will work, with strong determination, to provide even more diverse customers with a wide range of products.

Toshikazu Nishimoto

President

Tokyo Steel Co., Ltd.

Our Commitment

The Fifth Assessment Report of the Intergovernmental Panel on Climate Change (IPCC) released in October 2014 points out that an increase of two degrees Celsius in temperature from pre-industrial levels is highly likely to cause significant ecological and meteorological impacts, leading to serious problems, including a decrease in food production, large-scale migration, conflicts and poverty. The report also stresses the need to reduce GHG emissions by 40 to 70% compared with 2010 by the year 2050 and to near-zero by the end of this century in order to control the rise in temperature to within two degrees.

Under its Plan for Global Warming Countermeasures, the Japanese government aims at an 80% reduction in GHG emissions by 2050, and, to that end, sets a mid-term target of a reduction of 26% compared with 2013 by fiscal 2030. Drastic GHG reduction is a serious and pressing issue to be addressed on a global scale.

Meanwhile, increasing consumption of natural resources and increasing emissions of waste are becoming grave problems. It is predicted that world population will exceed nine billion by 2050 and that the current pace of consumption is not sustainable. Effective use of limited resources and achieving a recycling-based society are crucial in maintaining sustainable growth.

To solve these social issues, we will contribute to achieving a low-carbon society and recycling-based society by providing the world with higher-quality lower-cost products with lower environmental impact through the recycling of steel.

Steelmakers Must Do It

In Pursuit of a Low-Carbon Society

Steel, which is a metal that is very strong and can be mass-produced at a low cost, is indispensable to human life. Thanks to several technological innovations, steel is being used in diverse industries and is a building block of modern civilization.

In addition to its advantage in terms of production cost and productivity, steel is one of the most recyclable materials of all. In line with growing concerns over the depletion of natural resources, calls for the even more effective use of steel to achieve a recycling-based society are growing.

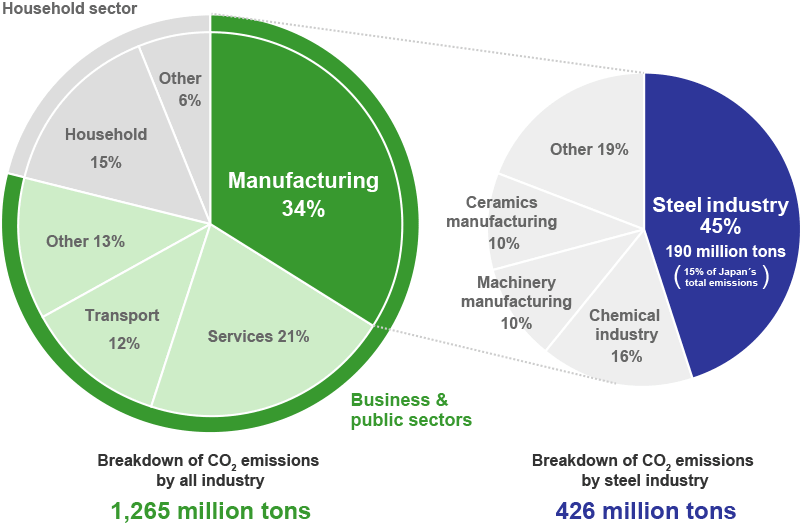

However, CO2 emissions from domestic steelmakers account for about 15% (190 million tons per year) of Japan’s total CO2 emissions (about 1,270 million tons per year).

We think that the steel industry, as the largest emitter among all industries, should assume more responsibility than other industries.

CO2 emissions by industry

Data compiled from fiscal 2014 greenhouse gas emissions figures published by Japan’s Ministry of the Environment, and other sources

Electric arc Furnaces Must Do It

In Pursuit of a Low-Carbon Society

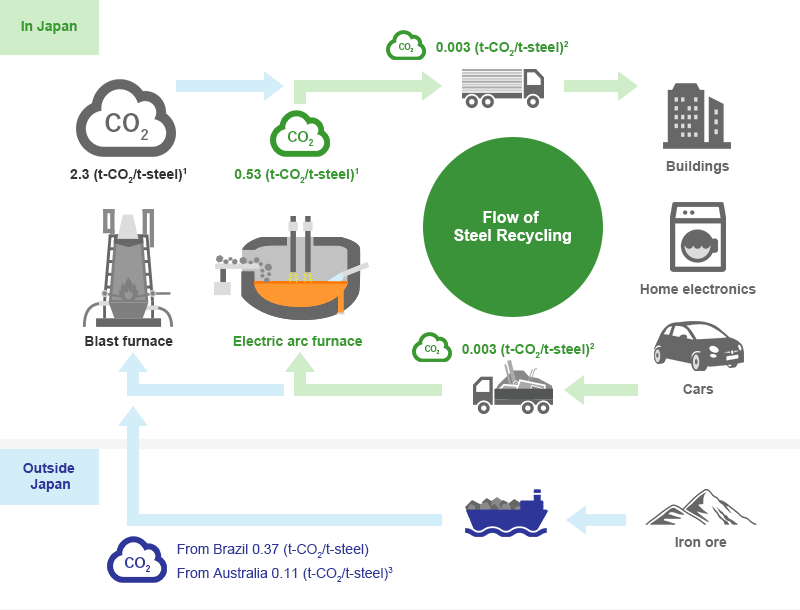

Of all CO2 emissions from the steel industry, 90% are emitted by steelmakers using blast furnaces.

It has been found that, in terms of CO2 emissions per production of one ton of steel, CO2 emissions from manufacturing by steelmakers using electric arc furnaces is only about one-quarter of that by steelmakers using blast furnaces.

The blast furnace process needs “reduction”—the removal of oxygen from iron oxide by using coal (coke) in order to extract the iron from iron ore—which involves large CO2 emissions. On the other hand, the electric arc furnace process produces iron by smelting steel scrap with electricity. CO2 emissions from the generation of that electricity at power plants account for most of the CO2 emissions from the electric arc furnace process. Even with the current energy mix, CO2 emissions from the electric arc furnace process are overwhelmingly less than those from the blast furnace process.

Advancement in the decarbonization of electricity due to the wider use of electricity generated from non-fossil fuels, including renewables, would further reduce CO2 emissions from the electric arc furnace process.

Additionally, in terms of CO2 generated in the process of transporting raw materials, electric arc furnace steel manufacturers, who operate within local communities to recycle locally sourced steel scrap on the basis of local production for local consumption, emit much less CO2 than blast furnace steel manufacturers, who import most of their raw materials.

CO2 emissions from Japan’s steel sector and

flow of steel recycling

1 Source: Makoto Nishino. “Theoretical Evaluation of CO2 emission by Integrated Steelmakers,” Bulletin of the Iron and Steel Institute of Japan Vol. 3 No. 1 1998.

2 Source: Ministry of Economy, Trade and Industry and Ministry of Land, Infrastructure, Transport and Tourism. “Guidelines for Calculating CO2 Emissions in the Logistics Sector.” 6.

3 Source: Ship & Ocean Foundation. A Report on Research Concerning the Reduction of CO2 Emissions from Vessels. 92. 2000. Assumption: Iron contained in iron ore is 60%.

CO2 emissions per one ton of crude steel: electric arc furnaces vs. blast furnaces

| Adjusted GHG emissions (t-CO2) | Crude steel production (t) | t-CO2/t-production | |

|---|---|---|---|

| Total of 10 electric arc furnace steelmakers | 5,662,532 | 12,405,170 | 0.46 |

| Total of 3 blast furnace steelmakers | 170,051,190 | 77,318,865 | 2.20 |

Less than 1/4

| Adjusted GHG emissions (t-CO2) | |

|---|---|

| Total of 10 electric arc furnace steelmakers | 5,661,532 |

| Total of 3 blast furnace steelmakers | 170,051,190 |

| Crude steel production (t) | |

|---|---|

| Total of 10 electric arc furnace steelmakers | 12,405,170 |

| Total of 3 blast furnace steelmakers | 77,318,865 |

| CO2t/t | |

|---|---|

| Total of 10 electric arc furnace steelmakers | 0.46 |

| Total of 3 blast furnace steelmakers | 2.20 |

Less than 1/4

Source: GHG emissions in fiscal 2013 calculated under the GHG Emissions Accounting, Reporting and Disclosure System and other sources

In Pursuit of a Recycling-Based Society

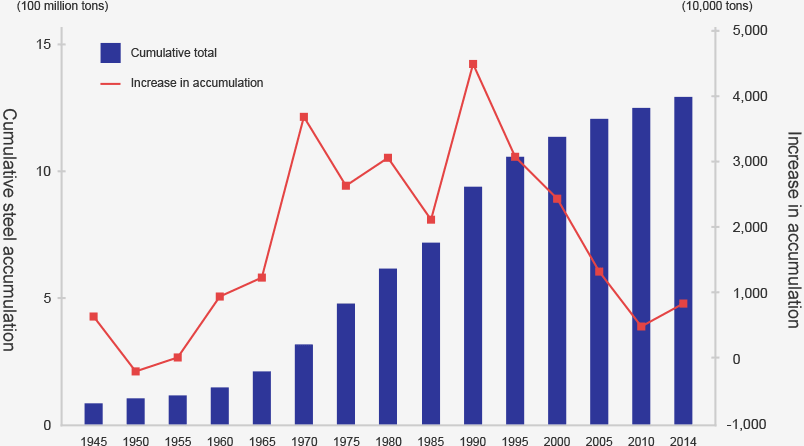

The estimated amount of accumulated steel in Japan as of 2015 is about 1,400 million tons, putting it behind only China, the EU, the United States and Russia. The amount of accumulated steel refers to the amount of steel resources used in steel products, accumulated in the form of buildings, bridges, automobiles, home appliances, etc., that will becomes future sources of scrap.

These resources will be collected as scrap in the future, and steelmakers using electric arc furnaces will regenerate them as steel resources.

Recycling Japan’s steel scrap, the accumulated amount of which is equivalent to 30 to 60 years’ worth of domestic steel demand, as a valuable resource is crucial in curbing the consumption of new natural resources and ensuring continued sustainable growth.

In the 1990s, however, steel scrap exports surpassed imports, reversing the trajectory of domestic steel accumulation (annual increase in accumulation) from an expansive to a shrinking trend. Since then, more than eight million tons of the valuable resource has continued to flow out of Japan every year.

Japan’s steel accumulation

Compiled based on data from the Japan Ferrous Raw Materials Association website

Tokyo Steel Must Do It

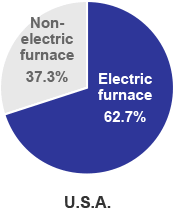

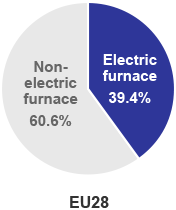

The percentage of steel produced with electric furnaces accounts for only 20% of all steel production in Japan, which is remarkably low compared with 60% in the United States and 40% in the EU.

One of the reasons for this situation—which persists despite the fact that Japan has more than 30 electric arc furnace steel manufacturers and boasts one of the world’s largest amounts of accumulated steel; that is, enough to allow the country to supply its needs—is that products manufactured by many steelmakers using electric arc furnaces have been limited to the so-called “electric arc furnace items,” such as round bars.

Percentage of production with electric furnaces around the world (2015)

Compiled based on data from the World Steel Association’s STEEL STATISTICAL YEARBOOK 2016

“We want to increase the presence of Japan’s electric arc furnace process to achieve a low-carbon society and establish a recycling-based society.”

To that end, we believe we must lead the effort, as we are the electric arc furnace steel manufactuer that has boldly taken on challenges to produce “blast furnance items,” such as H-beams and steel sheets, which electric arc furnace steel manufacturers traditionally have not produced, and we have widely supplied electric arc furnace steel products to society.

| Item | Market size in FY2015 (10,000 tons) | electric arc furnace’s share in FY2015 | Entry of Tokyo Steel |

|---|---|---|---|

| Round bars | 850 | 100% | 1953 |

| H-beams | 391 | 59.4% | 1969 |

| Heavy & medium plates | 1018 | 10.3% | 1984 |

| Hot rolled coils | 4231 | 2.5% | 1991 |

| Item | Round bars |

|---|---|

| Market size in FY2015 (10,000 tons) | 850 |

| electric arc furnace’s share in FY2015 | 100% |

| Entry of Tokyo Steel | 1953 |

| Item | H-beams |

|---|---|

| Market size in FY2015 (10,000 tons) | 391 |

| electric arc furnace’s share in FY2015 | 59.4% |

| Entry of Tokyo Steel | 1969 |

| Item | Heavy & medium plates |

|---|---|

| Market size in FY2015 (10,000 tons) | 1018 |

| electric arc furnace’s share in FY2015 | 10.3% |

| Entry of Tokyo Steel | 1984 |

| Item | Hot rolled coils |

|---|---|

| Market size in FY2015 (10,000 tons) | 4231 |

| electric arc furnace’s share in FY2015 | 2.5% |

| Entry of Tokyo Steel | 1991 |

Compiled based on a survey by Japan Metal Daily